BY JAMES MAY 2023

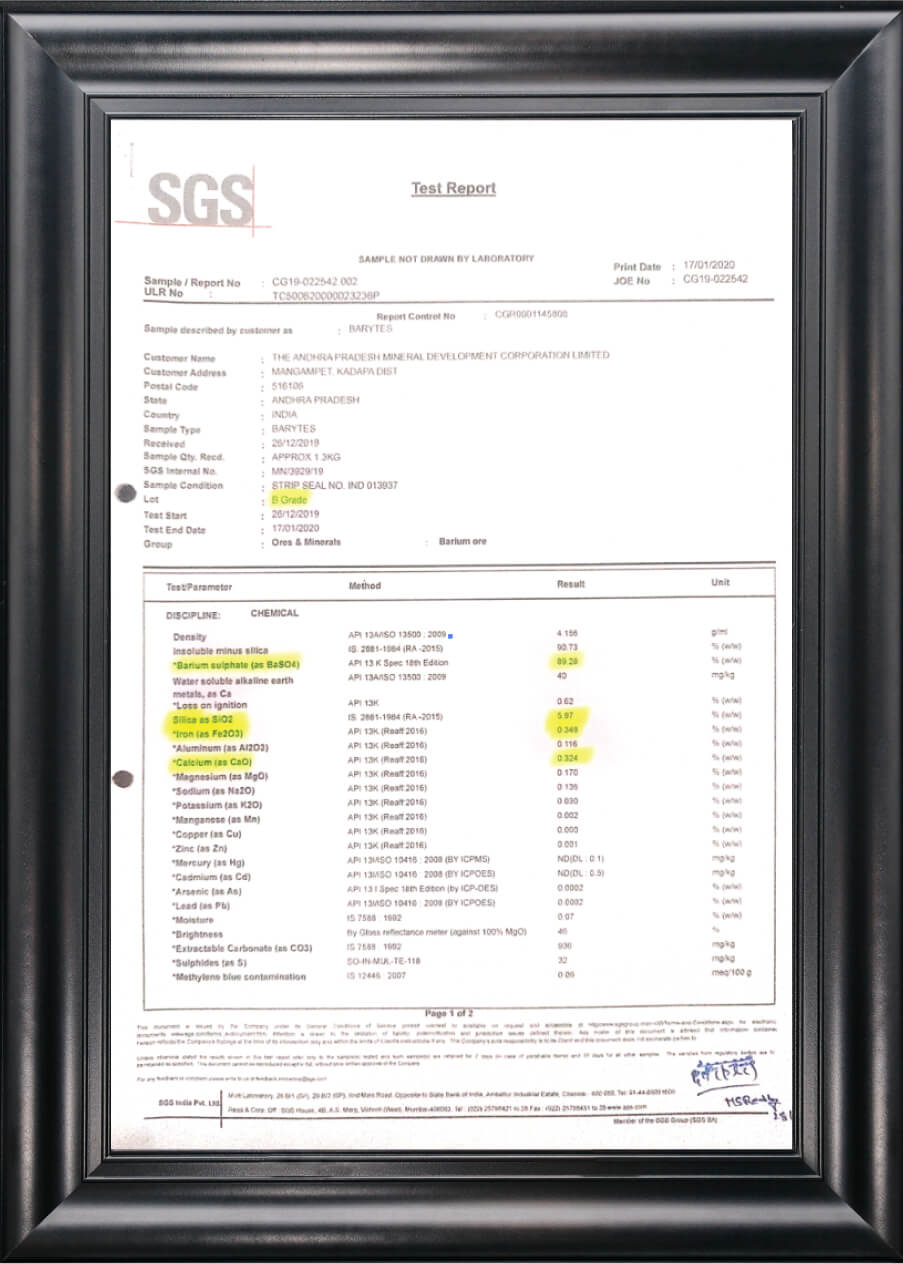

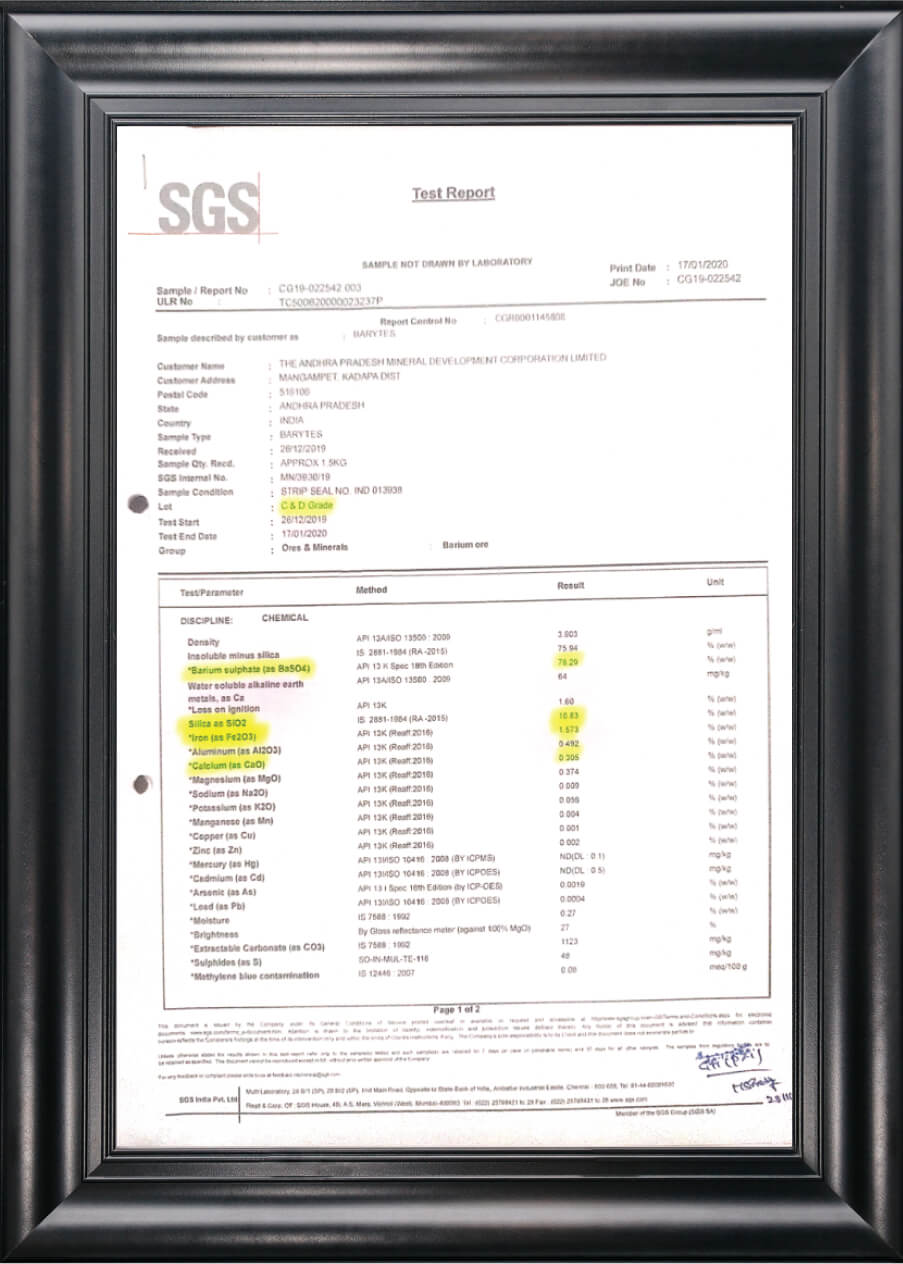

No machine or device is complete without plastic, rubber, and paint. Whether it is kitchen equipment, a toy, a car, or even an aircraft, these three materials are used in all of them. It could be about the upper body or internal components; the usage level in industries is extremely high. That is why you can not skip these materials when producing plastic and rubber components. From shine to toughness, many reasons exist to know what is behind these qualities. The material behind those qualities and features of plastic, rubber, and paints is barium sulfate. Some people also call it barite crystal. The reason why manufacturers use them is what you will read in this blog. If you are a small-scale producer of plastic and rubber products, this information will be really handy for you. Then, you will find better composition in the production method in order to achieve the best results. Remember that buyers use only durable products, and durability comes when one uses high-quality Barite to produce plastic, rubber, and paints. Chemical Formula and Density If you are a manufacturer or a retailer, this is for you. It is crucial to know such details when using chemicals for production. Each detail matters, and this is why you must know that the chemical formula of Barite is BaSO4. This will save you from any confusion during the production process in a factory. This must be known since every composition must be sharp in producing paints, plastic, rubber, or any product. On the other hand, you should be aware of the Barite’s nature. One of the things that needs to be known is that Barite is a heavy mineral. This is why barite density is 4.48 g/cm³, which is normally accepted in the industry. This is why it is also used in the construction drilling process. Its high density is the main reason. Moreover, the reason it is used in the production of plastic, rubber, and paints is its color range. You can usually find a barite color range in yellow, grey, light bluish, and brown shades. Buyers might face barite price challenges if you are dealing in these industries. Its prices might vary depending on the country because few countries have an abundant supply. Also, the platform or website that supplies it may offer discounts via bulk supply. So, you can find What is Barite Used for? Since we are discussing their prime use in producing paints, rubbers, and plastics, here are some main objectives why Barite is important. 1. As a Stiffener in Plastics and Rubbers People use some plastic and rubber goods that are soft and rigid. The rigidness comes from Barite. Without including it, manufacturers can not increase the hardness of these products. Since the density of barite minerals is high, it enhances the strength of plastic and rubber to show toughness. The stiffness comes in them when this material is added to the production. Then, the plastic and rubber products resist mild shocks and vibrations without risk of early breakage. Many auto parts and general plastic goods have ample toughness, which comes from Barite. 2. As a Pigments Strengthener Ever wonder why paints stay pigmented for a long time? That is because of Barite’s presence in them. When added to the paints, pigments last long enough to show durability. They strengthen the bond between the molecules of paint to create long-lasting effects. Then, they do not become pale or lack shine for better shelf life. Pigments are the primary element in paints that we use. Without a good pigment level, paint could lose its value. So, Barite is a foundation to provide them with strength. 3. Anti-Aging Agent in Paints Paints tend to last for months and even for years without showing signs of aging. If they age, that means they are close to expiry. To keep them fresh and usable, manufacturers use Barite in production. This is why one of the Barite uses is to prevent the aging process in paints. Once added to the paints, the freshness remains in them for a long time. You will not find any risk of foul smell or aging in paints because of Barite. 4. Enhances Weather Resistance Weather resistance is also very crucial in paints, plastics, and rubbers. Many products are used in open-air conditions where some or full exposure to environmental threats comes on them. This makes them vulnerable to damage, and manufacturers use Barite to enhance their resistance level. They extract raw Barite to bring the best quality of it. Then, it works well to strengthen paints against scratches and abrasions. Abrasions are very common in plastic and rubber products, where they need some protection. This protection comes from adding Barite in the production process. Once it is added, the durability against many weather impacts increases. As a result, plastic, rubber, and paints survive long enough amid rough conditions. 5. Improves Texture of Paints and Plastics Smooth texture and appearance in paints and plastics come from Barite. Without adding it, one can not get such an impressive surface in them. That is why Barite is a key element when manufacturing these products. Many products that are made of plastic involve Barite in their production. The texture becomes smooth so that the paint can create a stable and flat surface. The coat of paint becomes stable because of this element when used to improve texture. Final Words You can find a slight variance in the density of Barite in the market, but the standard one has been mentioned above. You will also see a little variance in the crystal shades, indicating the purity level. If you are purchasing it, choose the right supplier with competitive rates.